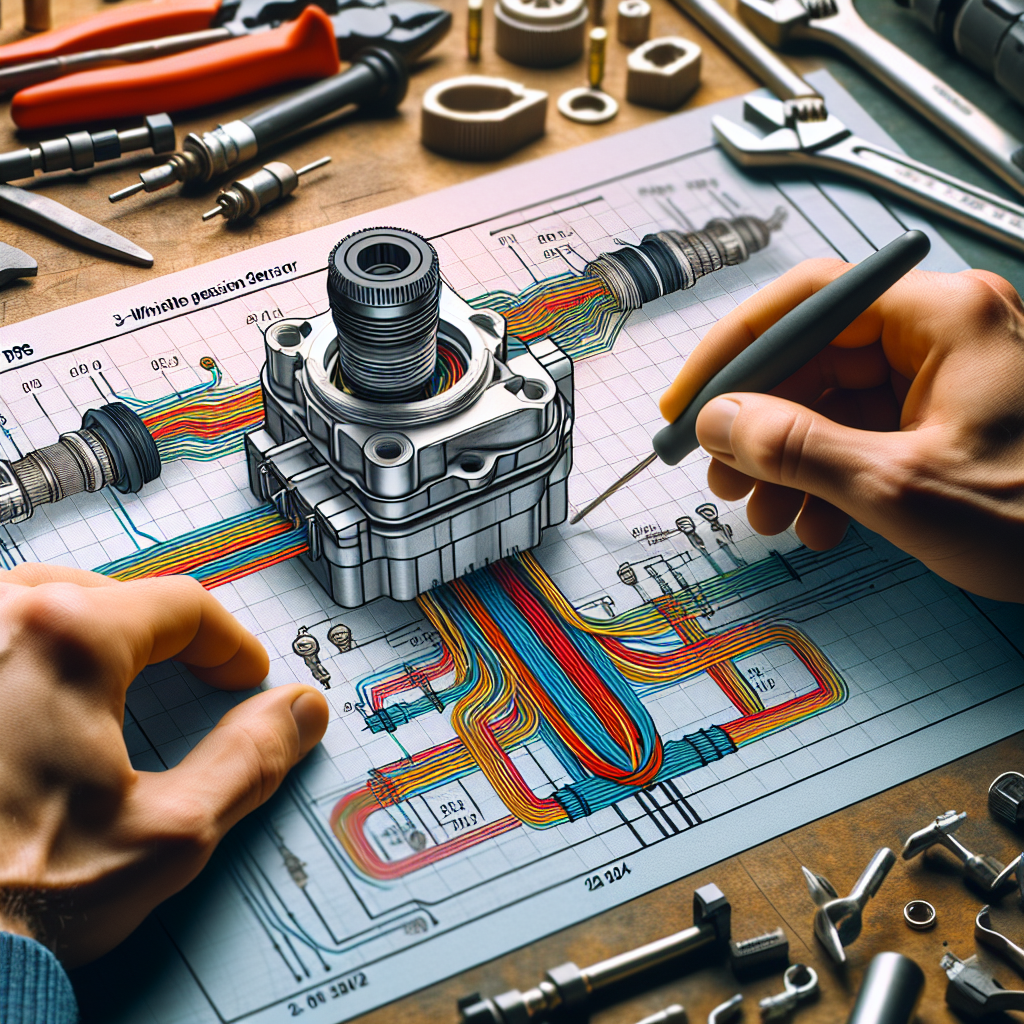

In modern automotive technology, the Throttle Position Sensor (TPS) plays a crucial role in optimizing engine performance and ensuring smooth operation. As vehicle enthusiasts and professionals transition to the 2024 models, it is essential to be well-versed in wiring a 3-wire TPS for optimal performance. In this comprehensive guide, I will share my firsthand experiences and expert insights to help you wire your TPS with confidence.

Introduction to the Throttle Position Sensor (TPS)

The Throttle Position Sensor (TPS) is a specialized sensor designed to monitor the position of the throttle in an internal combustion engine. It informs the engine control unit (ECU) about the throttle’s status, ensuring the proper delivery of fuel and air mixture for optimal engine performance. Knowing how to wire a 3-wire TPS correctly can make a significant difference in your vehicle’s functioning.

Tools and Materials You Will Need

Before diving into the wiring process, gather the necessary tools and materials to ensure a seamless experience:

- Screwdriver Set

- Wire Strippers

- Multimeter

- Electrical Tape

- 3-Wire TPS Sensor

- Wiring Diagram

- Heat Shrink Tubes

Having these tools at hand will streamline the process and minimize unexpected interruptions. It’s always better to be over-prepared than under-equipped.

Understanding the 3-Wire TPS

The 3-wire TPS is composed of three main wires:

- The Ground Wire (Black)

- The Variable Signal Wire (White/Yellow)

- The Reference Voltage Wire (Red/Orange)

Understanding the role of each wire is crucial for proper installation and functionality.

The Ground Wire (Black)

The ground wire serves as a common reference point to complete the electrical circuit. It connects the sensor to the engine’s grounding system, ensuring stable operation.

The Variable Signal Wire (White/Yellow)

The variable signal wire is responsible for transmitting the real-time throttle position to the ECU. This wire adjusts its voltage output based on the throttle’s angle.

The Reference Voltage Wire (Red/Orange)

The reference voltage wire provides a consistent 5V supply from the ECU to the TPS. This stability enables the TPS to measure the throttle position accurately.

Step-by-Step Wiring Process

Step 1: Disconnect the Battery

For your safety, the first step is to disconnect the vehicle’s battery. This precaution prevents any accidental short circuits or electrical shocks while working on the TPS.

Step 2: Locate the TPS

Locate the TPS on your vehicle’s throttle body. Typically, it is mounted on the side of the throttle body and is easily identifiable by its 3-wire connector.

Step 3: Prepare the Wiring

Strip a small section of insulation from each of the three wires on your new TPS. Ensure you have enough exposed wire to make solid connections.

Step 4: Connect the Ground Wire

Identify the vehicle’s ground connection point. Attach the ground wire (black) from the TPS to this point using a good-quality connector. Use your multimeter to ensure the ground connection is solid, providing a zero-ohm reading.

Step 5: Connect the Reference Voltage Wire

Locate the vehicle’s ECU reference voltage output, usually providing a 5V supply. Connect the reference voltage wire (red/orange) from the TPS to this output. Use heat shrink tubes to cover the connections, ensuring they are insulated and secure.

Step 6: Connect the Variable Signal Wire

Connect the variable signal wire (white/yellow) from the TPS to the corresponding input on the ECU. Again, use heat shrink tubes to cover the connections for effective insulation.

Step 7: Secure All Wiring

After making all necessary connections, use electrical tape to bundle the wires neatly. Ensure they are organized and free from any potential sources of friction or heat damage.

Step 8: Test the Connections

Reconnect the vehicle’s battery and start the engine. Use your multimeter to check the TPS output voltage while slowly opening and closing the throttle. The voltage should change smoothly and correspond to the throttle’s position.

Step 9: Fine-Tuning the TPS

Refer to your vehicle’s service manual to adjust the TPS properly. Some TPS units might require minor adjustments to align perfectly with the throttle body. Follow the manual’s instructions meticulously to ensure optimal performance.

Troubleshooting Common Issues

Despite following the wiring process accurately, you might encounter some common issues. Here are a few troubleshooting steps to resolve them:

- Inconsistent Throttle Response: Double-check all wire connections for stability and proper insulation.

- ECU Error Codes: Use a diagnostic tool to identify error codes related to the TPS and correct any wiring errors.

- Erratic Idle: Ensure the TPS is correctly calibrated according to the service manual.

Benefits of Proper TPS Wiring

Properly wiring and calibrating your TPS can lead to several benefits, including:

- Improved Fuel Efficiency: The ECU can adjust the air-fuel mixture more accurately, leading to better fuel economy.

- Enhanced Driveability: A correctly wired TPS ensures smooth and responsive throttle control.

- Reduced Emissions: Accurate throttle position data helps the ECU optimize combustion, reducing harmful emissions.

Important Safety Tips

Here are some essential safety tips to ensure a safe and successful wiring process:

- Always disconnect the battery before starting the wiring process.

- Use high-quality connectors and insulation materials to prevent electrical shorts.

- Double-check all connections with a multimeter to ensure accuracy.

- Follow your vehicle’s service manual for specific instructions and calibration procedures.

Frequently Asked Questions (FAQs)

Q1: Why is the Throttle Position Sensor important?

A1: The TPS is vital because it provides real-time throttle position data to the ECU, enabling the engine to adjust the air-fuel mixture for optimal performance.

Q2: How do I know if my TPS is faulty?

A2: Symptoms of a faulty TPS include erratic idle, poor acceleration, and ECU error codes. Using a multimeter to check for inconsistent voltage readings can help diagnose the issue.

Q3: Can I wire a 3-wire TPS myself, or should I seek professional help?

A3: With the proper tools and a detailed guide like this one, you can wire a 3-wire TPS yourself. However, if you’re unsure or uncomfortable, seeking professional help is always a safe choice.

Q4: What should I do if I encounter ECU error codes after wiring the TPS?

A4: Use a diagnostic tool to identify the specific error codes. Double-check the wiring connections and ensure the TPS is correctly calibrated according to your vehicle’s service manual.

By following this comprehensive guide, you can wire your 3-wire Throttle Position Sensor confidently, ensuring optimal performance for your vehicle in 2024 and beyond. For more in-depth tutorials, you can visit this automotive website, TPS wiring guide, or this detailed forum discussion. Happy wiring!