The Inspection Drones are coming

The inspection drones are coming. We do not necessarily consider inspection tasks to be particularly dangerous. But that’s probably because most of us have never had to. While there are certainly some inspection tasks that involve filling out forms and checking boxes, there are others that require daring feats like climbing to dizzying heights, braving elevated temperatures, or risking life and limb by entering inhospitable environments. Fortunately, drones are here to help.

By using a drone to collect visual data about the condition of an asset. Drone inspections help inspectors avoid dangerous situations. Inspection drones are transforming manual inspection processes. Enabling inspectors to speed inspection data collection . Also eliminate the slower manual steps that put them at risk.

For example, manual inspection of a cell tower may require climbing several stories into the air. On a tower to closely examine a guy wire. And manual inspection of an industrial boiler may require climbing fifty feet or more in the air on scaffolding.

A drone inspection service provider can fly an inspection drone around the cell tower. Capturing all the visual data the inspector needs to perform his inspection.

The use of drones offers advantages such as:

- Quick overview and status assessment

- Clear and detailed photographs of the defects.

- Preventive maintenance planning and optimized production

- Access to hard-to-reach areas

- Reduced downtime

- High level of security.

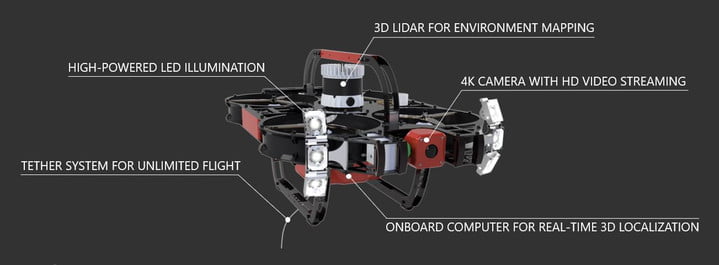

Mapping surroundings

Once it enters a dangerous environment, the drone uses its advanced laser sensors to create a 3D map of its surroundings. It then performs its inspection, using onboard 4K cameras as well as 3D markings on an associated map, so it can spot potential issues that may require maintenance.

“Although the system is currently pilot-driven, we continue to add flight control and navigation aids to reduce pilot stress and improve the safety of flight operations,” Skinner said. “

When researchers wanted to explore the world’s deepest ice caves, nearly 300 meters below ground level in the Greenland Ice Sheet, they turned to survey drones made by the Swiss company Flyability to accomplish the task. When the company isn’t being asked to help explore underground ice caves straight out of a sci-fi horror movie, its Elios 2 drones are used for visual assessment tasks in a host of scenarios where confined spaces represent a challenge for human inspectors.

Basically anywhere you don’t want to have to send a person, or that can be tricky, Flyability’s drones can help.

Add to that the 4,500 people injured and 60 killed each year due to scaffold-related accidents, and you can see how valuable drones can be in this space. “The use of drones for inspections, both internal and external, is increasing every year,” Zacc Dukowitz, marketing manager for Flyability, told Digital Trends.

A task ripe for automation

In the book Machine Platform Crowd by Andrew McAfee and Erik Brynjolfsson, the two researchers from the MIT Sloan School of Management classify the work that robots should ideally do as boring, dirty, dangerous, and costly (that is, costly). Drone inspection is a prime example. Much of the narrative around automation rightly focuses on the impact it could have on humans. After all, there’s something inevitably threatening about an automated process that promises to do your job faster and cheaper than you can, and to do it 24/7, without those pesky requests about weekends or the need to sleep at night.

But scenarios like these show where automation can be beneficial. With jobs like this done by drones, humans will be freed to focus on more valuable, less dangerous, and less complicated tasks. When it comes to monitoring infrastructure, this could translate to saving lives, either the lives of those conducting the inspections or those who may be harmed (or worse) by the failure of that infrastructure. This is one area where we should be more than willing to welcome our new drone overlords.

Typically, we recommend drone inspection for the following three categories:

- Constructions in the sea

The offshore environment is often seen as harsh and demanding, where minimizing breakdowns and production losses to plant and inspection equipment is essential. An example of a mission containing these items is a flare inspection on an oil and gas platform. Moreover the flare is still active. Here, drones collect images or thermographic data of the state of the flare. Data collection takes place in a turbulent. flame-filled environment. While the drone pilot, inspector and employees are at a safe distance. The inspection area, and therefore outside the risk area .

2. Constructions on land

Typically, drones are limited to flying at an altitude of 100 meters. FORCE Technology is use to carry out inspections at more than 100 meters. An example is the inspection of a 225-meter stack and masts at a power plant, refinery, or hydroelectric plant. Another area clearly suitable for drone inspection is bridges, whether on land, connecting islands, or crossing divides in a landscape.

In addition, drones give good results with ever higher wind turbines. In particular, leading edges, lightning rods and nacelles are subject to inspection. Here, the drone collects high-resolution images of possible faults. Which allows repair work to be organize in detail. The collected data will help avoid unpleasant surprises during the maintenance period.

3. Confined spaces

Confined spaces such as power plant boilers, etc. They are a relatively new addition to the drone inspection area. Moreover those are gradually becoming more common. Here, visual inspections are advantageous if scaffolding installation is too costly or time-consuming, or too dangerous for physical inspection. However, there are considerable challenges when operating drones in confined spaces, including lack of proper lighting conditions, color shading, radio signal reflection.

The technical possibilities

Today, there are simple drones that can record video or take still images. The advanced drones which all kinds of data collection equipment can be attached. It is particularly relevant to choose advanced drones.

In recent years we have also used the thermal imaging camera to inspect roofs of houses, electrical installations and production facilities. Facilitating the detection of breakdowns or defects related to heat

As explained it is especially at sea, on land, and increasingly in confined spaces. That drone inspection is the first choice. However, we will always clarify with the client whether drone inspection is the right option based on the nature of the problem and the data required.

Accepting that an important and important part of a drone inspection is the analysis of the data and images collected, it must be possible to ensure that the person performing the analysis is an expert in this field. Therefore, the client should ask for references from both the drone inspector and the data analyst.

THE PLACE OF INSPECTIONS IN THE MAINTENANCE PROCESS

Before we dive into the specific ways drones are used for visual inspections in various industries. Let’s first look at how inspections fit into the overall maintenance process. When servicing any type of asset.

By sending a UAV into a situation that would be dangerous to a person, such as a smokestack or cell tower, inspectors can collect visual data on the condition of an asset without exposing themselves to potential damage.

If an inspector discovers an issue that requires maintenance. Whether the issue is discovered by drone or another method. Subsequent repairs will still need to be done manually.

Sometimes inspectors may prefer to look at something with their own eyes to ensure a full 3D evaluation. Other times, an inspector may want to hook an inspection camera to a rope and drop it onto an asset. And sometimes a drone is the perfect tool for the job.

OIL & GAS DRONE INSPECTIONS

The oil and gas industry stores natural gas and gasoline, among other substances in pressure vessels and storage tanks. Using a drone for these inspections is beneficial. As it eliminates the need to build scaffolding to get a closer look inside the container. Protecting the inspector from harm and saving money by avoiding having to build scaffolding for inspection purposes.

Mining Drone Inspection

After a mining operation removes a vein of ore. The large underground hole left behind where the ore was mined can become incredibly unstable, with material falling from the ceiling and crumbling off the walls. Drones present a unique opportunity for the mining industry to collect data on stopes, ore passes and other areas of mining operations that would otherwise be impossible to collect.

Visual data of excavation sites collected by drones can provide previously impossible safety assessments, allowing unprecedented access to prohibited areas without exposing workers to underground hazards. Thanks to new mapping software, aerial data collected by drones can now be used to create 3D maps of the jobs. Which can then be compare to conditions before and after excavation to understand how the area has changed. Underground conditions can be incredibly unstable. Moreover the ability to collect visual data remotely. In a way that keeps mine personnel safe, is invaluable to the entire operation. And a third benefit comes in the form of potential savings through the identification of uncollected ore. The prevention of equipment loss by keeping it from entering areas with unstable conditions.

Infrastructure and Utilities Drone Inspections

Drones are used in infrastructure and public services for inspections related to regular maintenance, as well as for inspections after disasters such as hurricanes and floods, in which the status of existing infrastructure is unknown.

In scenarios that pose potential danger to inspectors, such as tower or bridge inspections, an added benefit is the ability to collect key visual data without the inspector needing to be physically present. To make this more concrete, visual inspection of a bridge without a drone can require inspectors to rappel into position, sometimes using heavy machinery to support the process, which can take days and be potentially dangerous. With a drone, inspectors can collect visual data from an entire bridge in just an hour or two and can conduct follow-up inspections more regularly because the cost and time required are much less.

Insurance Drone Inspection

The most common inspection use case for drones is inspecting roof damage after a major storm or hurricane. Instead of physically sending a person to a roof to inspect the damage, a drone inspection can quickly collect visual data about the roof’s condition and record it in a way that is easily accessible to the insurance company to validate the insurance claim.

When a natural disaster strikes, the need for certified commercial drone pilots in an area can increase as insurance companies scramble to hire enough pilots to meet their data collection needs.

Power Generation Drone Inspection

Power companies deal with several different types of assets that require regular inspections. These include assets used in coal-fired power generation, such as boilers and stacks, as well as those used in greener energy sources, such as wind turbines and various components of a hydroelectric plant.

The main advantages of a drone inspection over a traditional inspection, as in many inspection scenarios, are keeping the inspector out of harm’s way and saving money by not having to build scaffolding or other temporary infrastructure to support inspection efforts.

Public Safety Drone Inspection

Drone applications in public safety have grown rapidly in recent years. Some of the inspection scenarios where drones are used in public safety are live and ongoing events. Such as locating a missing person in a search and rescue operation. Moreover capturing aerial intelligence in an active fire scenario, or obtaining information about the spread of a forest fire. .

But public safety personnel also use drones for inspections in situations that are not active or ongoing. Such as using aerial data captured by a drone to create orthomosaic maps of public places to prepare for a potential active shooter scenario, or the use of aerial data to investigate a crime.

Sewer and Water Treatment Inspection

This inspections present several technical difficulties, and inspections related to sewerage and water treatment are certainly not inspections. Drones specially designed for indoor inspections help improve the inspection process in this industry by giving inspectors a close-up view of underground conditions without the need to enter the area being inspected.