Bench Milling Machine: How To Choose The Right One?

A bench milling machine is a small, portable mill that can be used to mill various materials. Bench milling machines are usually used for small, delicate jobs, such as milling circuit boards or jewelry. They can also be used for larger jobs, such as milling metal parts.

The Benefits of Bench Milling Machines

Bench milling machines are especially beneficial because they are small and portable. This means that they can be used in a variety of settings, such as in a home workshop or in a small business.

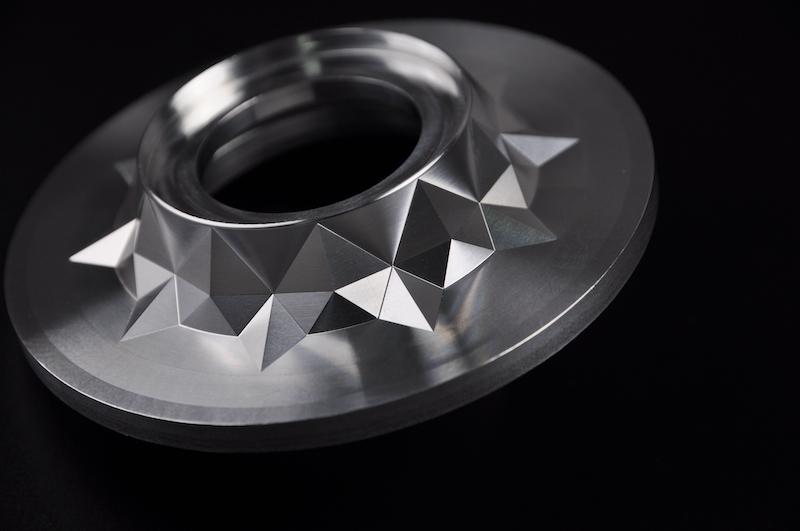

The milling machine is also very precise. This means that CNC milling can create very intricate designs here that would be impossible to create by hand.

Another benefit of bench milling machines is that they are relatively easy to use. This is especially true for those who have experience using other types of machinery.

Finally, bench milling machines are relatively affordable. This makes them a great option for those who are looking to add a milling machine to their workshop but don’t want to spend a lot of money.

Various Uses for Bench Milling Machines

Milling machines are some of the most versatile tools in any shop. Their versatility allows them to be used for a wide variety of tasks, including cutting, shaping, and drilling. Bench milling machines are among the most common type of milling machines and are typically used for smaller projects.

While bench milling machines have their limits, they are still capable of a wide variety of tasks. Here are some of the most common uses for bench milling machines:

1. Cutting

Bench milling machines can be used to cut a variety of materials. They can be used to cut metal, wood, plastic, and even stone. This makes them perfect for a wide range of projects, from creating metal parts to carving wooden sculptures.

2. Drilling

Bench milling machines can also be used for drilling. This is especially useful for creating large or deep holes. Drilling with a bench milling machine is also often faster and more accurate than doing it by hand.

3. Shaping

Bench milling machines can be used to create a variety of shapes. They can be used to create flat surfaces, curves, and even complex three-dimensional shapes. This makes them perfect for projects that require precision shaping, such as creating metal parts for machinery.

How to Choose the Right Bench Milling Machine

There are many factors that need to be considered when choosing the right bench milling machine for your needs. The first thing you need to do is determine the specific purpose that the machine will serve. Will it be used for light-duty tasks such as trimming small pieces of wood, or will it be needed to perform more heavy-duty work such as milling metal?

Once you know the specific purpose of the machine, you can begin to narrow down your choices. You’ll need to consider factors such as the size and weight of the workpiece, the power of the motor, and the type of table.

The size and weight of the workpiece are important because they will determine the size and weight of the bench milling machine itself. If you only need to perform light-duty tasks, then a smaller machine will suffice. However, if you’ll be performing heavier duty work, then you’ll need a larger and more powerful machine.

The power of the motor is another important consideration. If you only need to perform light-duty tasks, then a less powerful motor will suffice. However, if you’ll be performing heavier duty work, then you’ll need a more powerful motor.

The type of table is also an important consideration. There are two main types of tables: stationary and mobile. Stationary tables are attached to the bench milling machine itself, while mobile tables can be moved around. If you only need to perform light-duty tasks, then a stationary table will suffice. However, if you’ll be performing heavier duty work, then you’ll need a mobile table.

Conclusion

The right bench milling machine can make all the difference when it comes to performing tasks in the workshop. Be sure to consider all of the factors involved in choosing a machine before making your final decision. With a little bit of research, you’ll be able to find the perfect machine for your needs.