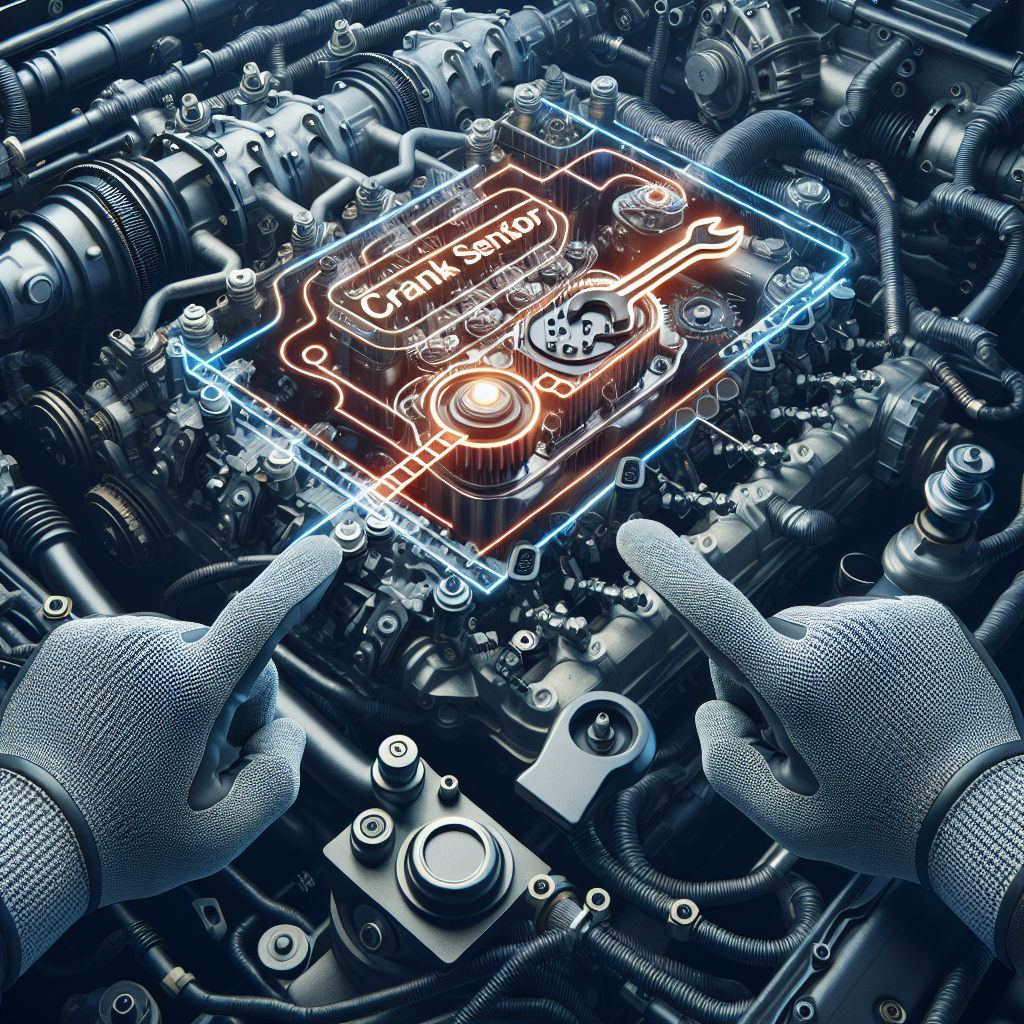

Maintaining your vehicle is crucial for its longevity and performance. Among the myriad of components under your car’s hood, the crank sensor, particularly in LS engines, plays a significant role. Knowing how to locate it is essential whether you are a novice or an experienced car enthusiast. In this comprehensive guide, I will take you through the step-by-step instructions to locate the LS crank sensor in your vehicle.

Understanding the LS Crank Sensor

The LS crank sensor is pivotal in monitoring the rotational speed of the crankshaft in an LS engine. This data is vital for the engine control unit (ECU) to optimize fuel injection and ignition timing. If the crank sensor malfunctions, it can lead to a variety of problems ranging from poor fuel economy to engine stalling and even a no-start condition.

Tools You’ll Need

Before diving into the step-by-step process, it’s essential to gather the necessary tools to make the task easier:

- Socket set

- Ratchet wrench

- Screwdrivers (Flat-head and Phillips)

- Flashlight

- Multimeter (optional for testing)

- Service manual for your vehicle

Ensuring you have these tools readily available will streamline the process and reduce frustration.

Step-by-Step Instructions

Step 1: Safety First

Before starting any work on your vehicle, always prioritize safety. Make sure the engine is cool to avoid burns. Wearing safety gloves and goggles can also protect you from potential injuries.

Step 2: Disconnect the Battery

Locate the vehicle’s battery, usually found in the engine bay or trunk. Carefully disconnect the negative terminal first, followed by the positive terminal. This will prevent any accidental electrical shorts during the process.

Step 3: Locate the Crank Sensor

In an LS engine, the crank sensor is usually located near the rear of the engine block, adjacent to the starter motor. In some models, it might be positioned near the crankshaft pulley at the front. Refer to your vehicle’s service manual to get the exact location.

Step 4: Remove Obstructions

Depending on your vehicle model, you may need to remove certain components to access the crank sensor. This might include the starter motor or other engine accessories. Use the socket set and ratchet for this task. Keep track of all bolts and screws you remove using a small container to avoid misplacements.

Step 5: Disconnect the Crank Sensor Connector

Once you’ve located the crank sensor, you will see an electrical connector attached to it. Carefully disconnect this connector. It might have a locking tab that you need to press to release.

Step 6: Unbolt the Crank Sensor

The crank sensor is secured by one or two bolts. Use the appropriate socket size to remove these bolts. Gently wiggle the sensor to take it out of its seated position without damaging it.

Step 7: Inspect the Crank Sensor

Before installing a new sensor, compare it with the old one to ensure they are identical. Inspect the old sensor for any signs of damage or wear.

Step 8: Install the New Crank Sensor

Carefully place the new crank sensor in the same position as the old one. Secure it with the bolts you removed earlier, ensuring a snug fit without over-tightening.

Step 9: Reconnect the Electrical Connector

Attach the electrical connector back to the crank sensor. Ensure it clicks into place securely.

Step 10: Reassemble Removed Components

If you had to remove any components to access the crank sensor, now is the time to reassemble them. Secure all bolts and screws tightly.

Step 11: Reconnect the Battery

Reconnect the vehicle battery, starting with the positive terminal followed by the negative terminal. Ensure the connections are tight.

Step 12: Test the Sensor

Start the engine to see if the new crank sensor is functioning correctly. If the engine starts smoothly and there are no error codes, you have successfully located and replaced the LS crank sensor.

Common Issues with Crank Sensors

Symptoms of a Failing Crank Sensor

A failing crank sensor can manifest through various symptoms. These include:

- Engine Misfires: An irregular signal from the crank sensor can cause the engine to misfire.

- Poor Fuel Economy: The ECU may not optimize fuel injection properly.

- Difficulty Starting the Engine: The engine may crank but not start.

- Check Engine Light: The light will illuminate, often accompanied by a diagnostic trouble code related to the crank sensor.

Testing the Crank Sensor

If you’re unsure whether the crank sensor is faulty, you can use a multimeter to test it. Check the resistance between the sensor terminals. Refer to your vehicle’s service manual for specific resistance values.

Frequently Asked Questions

What is the average lifespan of a crank sensor?

Crank sensors typically last around 100,000 miles, but this can vary based on driving conditions and maintenance.

Can I drive with a faulty crank sensor?

While it might be possible, driving with a faulty crank sensor is not advisable as it can lead to engine stalling and other serious issues.

How much does it cost to replace a crank sensor?

The cost can vary, typically ranging from $100 to $250, which includes parts and labor.

Can a bad crank sensor cause transmission problems?

Yes, since the crank sensor data is critical for engine timing, a faulty sensor can indirectly affect transmission performance.

Conclusion

Locating and replacing the LS crank sensor in your vehicle is a vital skill that can save you time and money. This guide provides a thorough, step-by-step approach to make the task easier, even for beginners. Ensuring your crank sensor is in good working condition will help maintain your engine’s performance and longevity.

Happy tinkering with your vehicle!

Frequently Asked Questions

1. What are the common symptoms of a faulty LS crank sensor?

A faulty LS crank sensor can cause engine misfires, poor fuel economy, difficulty starting the engine, and may illuminate the check engine light with related error codes.

2. How often should the crank sensor be inspected?

The crank sensor should be inspected every 30,000 miles during routine maintenance to catch early signs of wear or failure.

3. Can I test my crank sensor without disconnecting it?

Yes, you can perform basic tests, such as checking for engine fault codes or using a multimeter to measure signal output without fully disconnecting the sensor.

4. Is it possible to clean a crank sensor instead of replacing it?

In some cases, if the sensor is merely dirty, cleaning it might help. However, replacing a malfunctioning sensor is generally recommended.