The Role of Printed Circuit Board Assembly in Modern Electronics

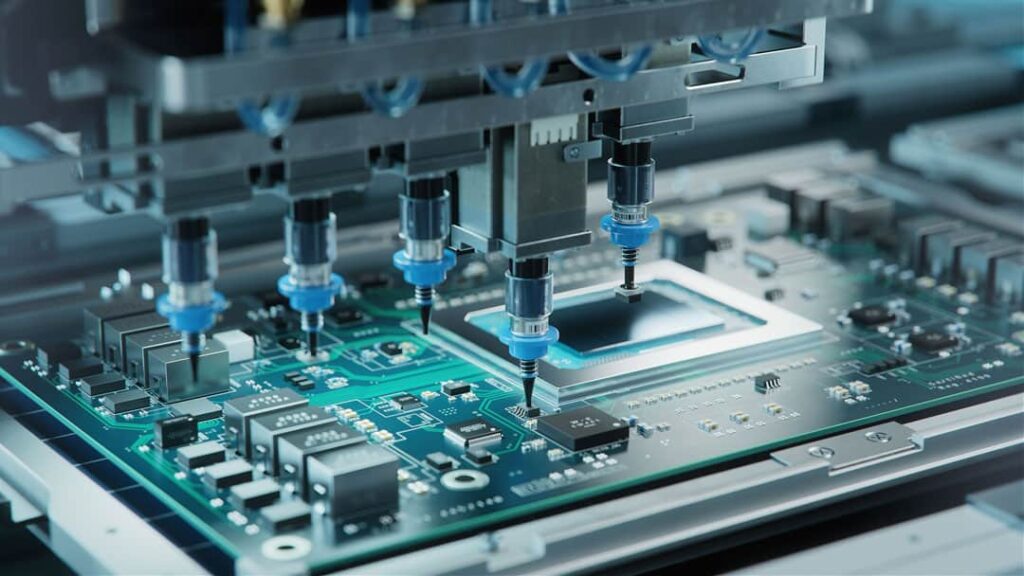

We live in a world where electronic devices are constantly evolving—getting smaller, faster, and more efficient. But have you ever wondered what makes this possible? Behind every sleek smartphone, cutting-edge medical device, or advanced industrial system, there’s a carefully designed and laid-out Printed Circuit Board (PCB) bringing everything to life.

In this post, we’re going to dive into why PCB design and layout are so essential in the world of modern electronics. From making sure a product works reliably to ensuring that it’s easy to manufacture, PCB design is where the magic happens before assembly even begins.

Why PCB Design Matters

Before any circuit board is assembled, the design and layout are meticulously planned. Why is this step so important? Let’s break it down:

- Functionality – The design phase ensures that the board will perform its intended tasks. A well-designed PCB allows for efficient electrical signals, which means your device will work as expected—whether it’s a heart monitor or an industrial sensor.

- Space Optimization – With gadgets becoming smaller, packing more power into less space is essential. Proper PCB layout design ensures that components are placed efficiently, maximizing performance without wasting space. This is key in industries like telecommunications and consumer electronics, where every millimeter counts.

- Manufacturability – Designing for manufacturability (DFM) is critical. A good PCB design doesn’t just work well in theory; it’s also optimized for the production process. This ensures the transition from prototype to mass production is smooth and cost-effective.

- Testability – Before any product hits the market, it needs to be thoroughly tested. Design for testability (DFT) ensures that the PCB can be easily and accurately tested for faults during production, preventing issues down the line.

- Longevity and Reliability – A good design considers how the board will be used. Will it be exposed to extreme temperatures or vibrations? PCB designers consider these factors to ensure that the board remains reliable throughout its lifetime, no matter the environment.

Key Considerations in PCB Design

Creating a successful PCB isn’t as simple as throwing components onto a board. There are several factors that must be considered during the design and layout process to ensure that the final product is both functional and efficient. Let’s take a look at a few critical considerations:

1. Component Placement and Routing

The placement of components is one of the most important aspects of PCB design. The designer needs to think about how each component interacts with the others, both electrically and thermally. Good placement reduces interference and heat buildup, improving the overall performance and lifespan of the device.

Once components are placed, the next step is routing the traces—essentially the “wires” that connect everything. Proper routing ensures that signals travel efficiently without interference or loss, which is crucial for the board’s performance.

2. Layering

For more complex electronics, single-layer PCBs may not cut it. Multi-layer printed circuit board assembly services allow for more components and more sophisticated circuits while keeping the design compact. However, this adds complexity to the design process. Designers need to carefully consider how signals will move between layers and ensure they don’t create unwanted noise or interference.

3. Thermal Management

Electronics generate heat, and if that heat isn’t managed properly, it can lead to failures or reduced performance. Designers must think about how heat will move through the board and use techniques like thermal vias or heatsinks to dissipate it effectively. This is especially important in industries like aerospace or automotive, where extreme conditions are the norm.

4. Power Distribution

Ensuring the right amount of power reaches each component without fluctuations is another critical aspect of PCB design. Poor power distribution can lead to unstable operation, reduced performance, or even permanent damage to components. Careful planning during the design phase ensures a stable and reliable power supply across the board.

5. Signal Integrity

High-speed circuits can be particularly sensitive to signal integrity issues. Designers need to ensure that signals travel cleanly between components without degradation. This means managing issues like electromagnetic interference (EMI), crosstalk between traces, and ensuring proper grounding.

The Impact of a Strong PCB Design Process

A well-executed PCB design sets the foundation for a seamless transition into production and high-quality end products. Here’s why a robust design process is so vital:

- Speed to Market – Getting products to market quickly is essential in today’s competitive landscape. A strong PCB design process means fewer revisions and fewer production delays. When you get the design right the first time, you save time and money by avoiding costly reworks.

- Cost Efficiency – A smart design takes manufacturing into account. By optimizing the layout for assembly, designers can reduce the cost of producing the board. Fewer errors during production, more efficient use of materials, and the ability to scale production are just some of the benefits of a well-thought-out design.

- Custom Solutions for Complex Needs – PCB design is never one-size-fits-all. Each product or industry has its unique requirements. For example, a PCB for a medical device needs to be designed with precision and reliability in mind, while an automotive PCB must withstand temperature fluctuations and vibrations. A flexible design process allows for tailored solutions that meet the specific needs of each application.

- Product Reliability – Products with poorly designed PCBs often experience performance issues or failures down the line. A solid design process ensures that every element is considered, from power distribution to heat management, resulting in more reliable devices that last longer.

Industries that Rely on Expert PCB Design

PCB design is a key factor in a wide range of industries. Here are just a few areas where expert PCB design plays a crucial role:

- Telecommunications – The rapid transmission of data, whether through fiber optics or mobile networks, relies heavily on well-designed PCBs that can handle high-speed signals without interference.

- Medical Devices – In the medical field, reliability and precision are non-negotiable. Devices like pacemakers, imaging equipment, and monitoring devices depend on expertly designed PCBs to function flawlessly.

- Aerospace – Space and aviation industries push technology to its limits, requiring PCBs that can withstand harsh conditions like extreme temperatures, vibrations, and radiation.

- Consumer Electronics – From smartphones to wearables, consumer devices rely on compact, powerful PCBs to deliver the performance users expect in smaller and smaller packages.

- Automotive – Modern vehicles are essentially computers on wheels, with systems for navigation, safety, and entertainment all powered by intricate PCBs.

In conclusion, PCB design and layout are the foundation of modern electronics, providing the structure and reliability necessary for today’s complex devices. A thoughtful design process not only ensures that products function as intended but also saves time, reduces costs, and leads to more reliable, long-lasting devices. As industries push the boundaries of what technology can do, the role of expert PCB design will only continue to grow.