In the complex world of automobile engines, understanding how the different sensors work together to ensure smooth operation can be crucial. One such component that plays a vital role in maintaining the optimum performance of an engine is the Idle Air Control (IAC) sensor. This 2024 guide will delve into how the IAC sensor lets the Engine Control Module (ECM) control engine idle effectively. Whether you’re a seasoned mechanic or a car enthusiast looking to deepen your knowledge, this comprehensive guide is tailored just for you.

What is an Idle Air Control (IAC) Sensor?

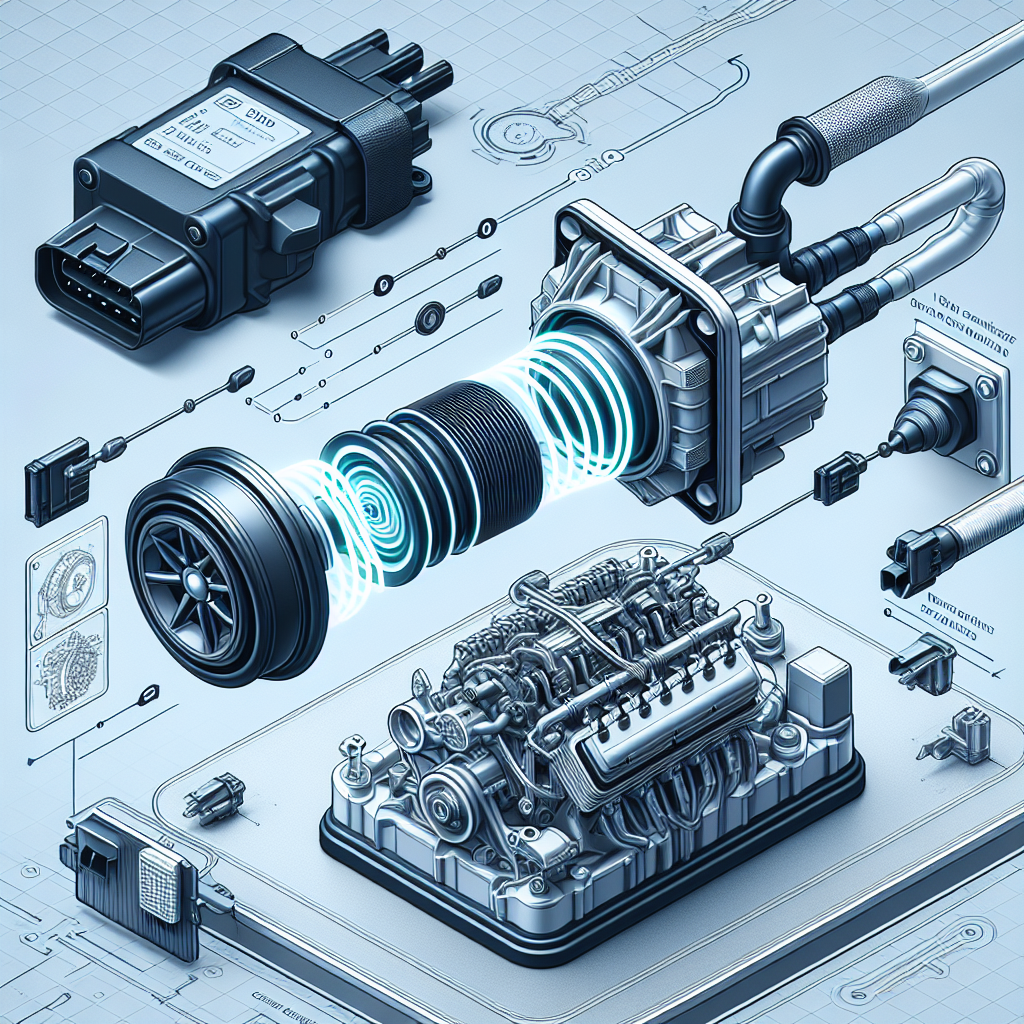

The Idle Air Control (IAC) sensor is a small but significant component situated in the vehicle’s throttle body, near the intake manifold. Its primary function is to regulate the amount of air entering the engine while the vehicle is idling. By doing so, it ensures that the engine runs smoothly without stalling or racing. Proper control over idle speed not only improves fuel efficiency but also reduces emissions.

Functionality of the IAC Sensor

When you start your car, the engine is in a state of no load, meaning it’s not doing significant work like moving the car or powering auxiliary components. The IAC sensor works with the ECM to manage idle speed based on various inputs such as engine temperature, load on the electrical system, and whether the air conditioning is on or off.

The sensor measures the amount of air bypassing the throttle. This data is then transmitted to the ECM, which makes adjustments to the throttle position, altering the air-fuel mixture to optimize engine idle speed.

How the ECM Utilizes the IAC Sensor

The Engine Control Module (ECM) is the brain of the engine management system. It receives data from various sensors, including the IAC sensor, to make real-time adjustments for optimal performance. When the ECM receives data from the IAC sensor indicating that more or less air is needed, it adjusts the throttle position accordingly.

Components Involved in Idle Control

- Throttle Position Sensor (TPS)

- Mass Air Flow (MAF) Sensor

- Coolant Temperature Sensor

- Oxygen Sensor

These components work harmoniously with the IAC sensor to maintain the required idle speed.

Common Problems and Solutions Related to the IAC Sensor

Understanding common IAC sensor problems can save you time and money. Typical issues include stalling, high idle, rough idle, or even a failed emissions test.

Diagnosing IAC Sensor Problems

Before replacing an IAC sensor, it’s crucial to diagnose if it’s indeed the problematic part. The following steps offer a basic diagnostic process:

- Visual Inspection: Check for visible damage or dirt buildup.

- Using a Diagnostic Tool: Plugging into the OBD-II port can provide error codes related to the IAC sensor.

- Manual Testing: Utilizing a multimeter can help verify the sensor’s functionality.

If these diagnostic steps point towards a faulty IAC sensor, replacing it or cleaning it might be necessary.

Replacing the IAC Sensor

Replacing an IAC sensor is relatively straightforward but varies based on the make and model of the vehicle.

Steps to Replace the IAC Sensor

- Disconnect the Battery: Always disconnect the battery to avoid short circuits.

- Locate the IAC Sensor: Usually found near the throttle body.

- Remove Mounting Bolts: Use a wrench to remove the sensor from its place.

- Disconnect Wiring Harness: Carefully disconnect the sensor’s wiring.

- Install the New Sensor: Reverse the removal process to install the new IAC sensor.

- Reconnect the Battery: Once everything is secure, reconnect the battery.

Things to Keep in Mind

- Ensure the new sensor matches the specifications of the old one.

- After installation, you may need to reset the ECM or conduct a relearn procedure.

For more detailed guides, check out this Complete IAC Sensor Replacement Guide.

Benefits of a Well-Functioning IAC Sensor

A well-functioning IAC sensor ensures that your engine idle is smooth, consistent, and efficient. It leads to better fuel economy and reduces wear and tear on the engine. Additionally, it helps in maintaining engine longevity and ensures that your vehicle meets emission standards.

Long-term Advantages

- Enhanced Engine Performance: A balanced air-fuel mixture leads to optimal combustion.

- Reduced Emissions: Proper idle control can minimize harmful emissions.

- Fuel Efficiency: Less fuel is wasted during idle phases.

The Role of the ECM in Modern Vehicles

Modern vehicles rely heavily on the ECM to manage various aspects of engine performance. The ECM uses inputs from multiple sensors to make precise adjustments in real-time.

Integration with Other Systems

The ECM not only oversees the engine but also integrates with systems like the transmission, brakes, and even the infotainment system. In a way, it acts as the central nervous system of the vehicle.

Common Myths About IAC Sensors

There’s a lot of misinformation regarding IAC sensors. Let’s address some common myths:

Myth 1: IAC Sensors Do Not Affect Fuel Efficiency

Fact: A malfunctioning IAC sensor can lead to poor air-fuel mixtures, affecting fuel efficiency.

Myth 2: Cleaning the IAC Sensor is Unnecessary

Fact: Dirt and grime can impede the sensor’s functionality; periodic cleaning is essential.

Myth 3: IAC Sensors Only Affect Idle

Fact: While primarily designed for idle control, a faulty IAC sensor can also impact overall engine performance.

Essential Tools for IAC Sensor Maintenance

Having the right tools for maintaining your IAC sensor can make the job easier and more efficient.

Recommended Tools

- OBD-II Scanner: For diagnosing error codes.

- Multimeter: For manual testing.

- Cleaning Supplies: Such as throttle body cleaner and a lint-free cloth.

- Basic Hand Tools: Wrenches and screwdrivers.

Investing in quality tools can save time and help you maintain your vehicle better.

How to Extend the Life of Your IAC Sensor

While IAC sensors are robust, they can benefit from proper maintenance.

Maintenance Tips

- Regular Cleaning: Keep the sensor and throttle body clean.

- Periodic Inspections: Regularly check for signs of wear or damage.

- Timely Replacements: Replace the sensor if it shows consistent signs of malfunction.

Following these tips can extend the life of your IAC sensor and, by extension, your vehicle’s engine.

Conclusion

Understanding and maintaining your vehicle’s IAC sensor is crucial for optimal engine performance. This 2024 guide has provided a thorough overview of how the IAC sensor collaborates with the ECM to control engine idle, along with practical advice for diagnostics, replacements, and maintenance. Proper care and attention to this small component can yield significant benefits for your vehicle. Whether you’re aiming to improve fuel efficiency or reduce emissions, a well-functioning IAC sensor is indispensable.

For more detailed information, check out these resources:

Frequently Asked Questions

1. How can I tell if my IAC sensor is malfunctioning?

A malfunctioning IAC sensor often leads to erratic idle speeds, stalling, rough idle, or high idle. Using an OBD-II scanner can help diagnose such issues by providing relevant error codes.

2. Can I clean my IAC sensor instead of replacing it?

Yes, cleaning your IAC sensor can often restore its functionality, provided the problem is due to a buildup of dirt and grime. Use specialized throttle body cleaners for this task.

3. How often should I inspect my IAC sensor?

It’s advisable to inspect the IAC sensor during routine maintenance, generally every 30,000 miles. However, if you notice symptoms like erratic idling, immediate inspection is recommended.

4. What tools do I need to replace the IAC sensor?

The essential tools for replacing an IAC sensor include a wrench set, a multimeter, and an OBD-II scanner. Additional supplies like throttle body cleaner can be helpful if you intend to clean the sensor before replacing it.