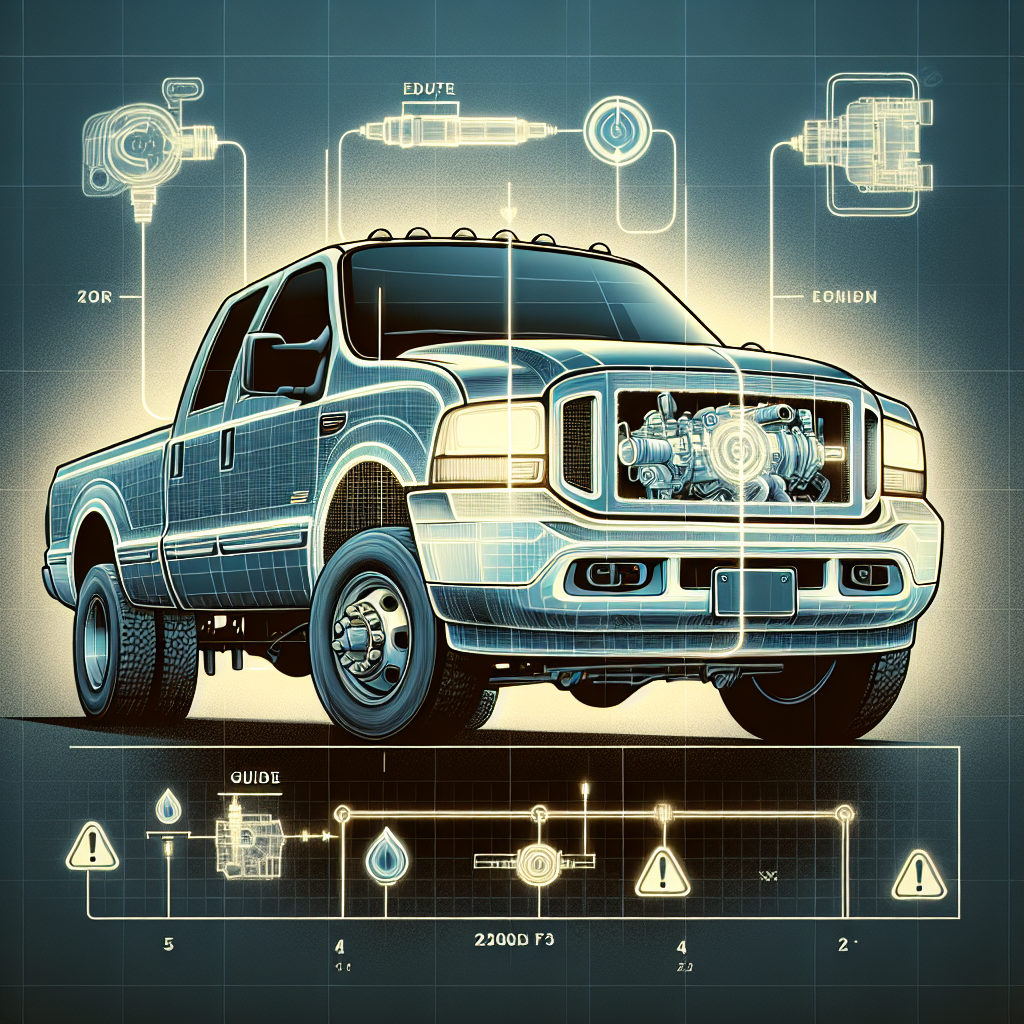

Owning a classic diesel powerhouse like the 2000 Ford F250 7.3 can be both a joy and a challenge. One of the common issues that can arise is with the Throttle Position Sensor (TPS). Understanding how to identify and address TPS symptoms can save you from headaches and costly repairs. In this comprehensive guide, I’ll walk you through everything you need to know to keep your 2000 Ford F250 running smoothly.

Understanding the Throttle Position Sensor

Before diving into symptoms, it’s crucial to understand what a Throttle Position Sensor (TPS) does. The TPS is a vital component of your truck’s fuel management system. It measures the angle of the throttle valve and sends this information to the engine control unit (ECU). This data helps in adjusting the air-fuel mixture, improving engine performance, and ensuring fuel efficiency.

Symptoms of a Failing Throttle Position Sensor

Identifying a failing TPS early can prevent extensive damage and poor engine performance. Here are the most common symptoms you should watch out for:

Engine Hesitation

One of the first signs is engine hesitation. When you press the accelerator, you may notice a delay in the engine’s response. This hesitation can lead to unsafe driving conditions, especially in heavy traffic.

Erratic Idle

A defective TPS can cause the engine to idle erratically. You might notice the RPM fluctuating without any input from you. This erratic behavior can make your truck hard to control, especially at low speeds.

Poor Fuel Economy

A faulty TPS can lead to improper air-fuel mixture regulation, causing your truck to consume more fuel than necessary. If you find yourself making frequent trips to the gas station, the TPS could be to blame.

Stalling

Intermittent stalling is another clear sign. If your truck suddenly dies while idling or during acceleration, the TPS might be malfunctioning. Stalling can be both dangerous and inconvenient.

Acceleration Issues

Noticeable acceleration issues such as a lack of power or slow response when pressing the gas pedal can indicate a problem with the TPS. This issue can become more pronounced when towing heavy loads, a common scenario for an F250 owner.

Check Engine Light

Lastly, a glowing Check Engine Light (CEL) often signals that there’s something wrong with the TPS. While the CEL can illuminate for various reasons, a diagnostic scan can pinpoint whether the TPS is the culprit.

How to Diagnose a Bad Throttle Position Sensor

Diagnosing a bad TPS requires a few basic tools and some patience. Here’s a step-by-step process to help you confirm your suspicions:

Step 1: Visual Inspection

Start by performing a visual inspection of the sensor and its connections. Look for any signs of wear or damage, like frayed wires or connectors that are loose.

Step 2: Use a Diagnostic Scanner

A diagnostic scanner can read the error codes stored in your truck’s ECU. Codes like P0120 (Throttle Position Sensor/Switch "A" Circuit Malfunction) can indicate a faulty TPS.

Step 3: Multimeter Test

A multimeter can help test the sensor’s resistance. Set it to measure ohms and connect the probes to the TPS terminals. You’re looking for a smooth, linear increase in resistance as you move the throttle; any spikes or drops indicate a faulty sensor.

Step 4: Voltage Test

You can also measure the voltage output of the TPS. Connect the multimeter probes to the sensor’s signal wire and ground. With the ignition on (engine off), slowly press the throttle and observe the voltage readings. They should increase smoothly from approximately 0.5V at idle to about 4.5V at full throttle.

Replacing the Throttle Position Sensor

Once you’ve confirmed that your TPS needs replacing, the next step is swapping it out for a new one. While it’s a relatively straightforward process, having a step-by-step guide can make things smoother:

Gather Your Tools

Before starting, ensure you have the necessary tools:

- New TPS

- Screwdrivers

- Socket set

- Multimeter

- Torque wrench

Remove the Old TPS

- Disconnect the Battery: Safety first! Disconnect the negative terminal of the battery to avoid any electrical mishaps.

- Locate the TPS: On the 7.3 Powerstroke, the TPS is usually mounted on the throttle body.

- Remove the Connector: Carefully disconnect the electrical connector from the TPS.

- Unscrew the TPS: Use a screwdriver or socket set to remove the screws holding the TPS in place.

Install the New TPS

- Position the New TPS: Align the sensor with the throttle body and screw it in place.

- Reconnect the Connector: Attach the electrical connector securely.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Test the Installation: Turn on the ignition and verify the new TPS is functioning correctly by observing the idle and throttle response.

Reset the ECU

After installing the new sensor, it’s a good practice to reset the ECU. This can be done by disconnecting the battery for about 30 minutes to clear any stored error codes.

Maintenance Tips for Throttle Position Sensor

Regular Inspections

Perform regular visual inspections of the TPS and its connections. Look for any signs of wear and tear, frayed wires, or corrosion.

Cleanliness is Key

Keep the throttle body and surrounding areas clean. Contaminants can affect the smooth operation of the TPS. Use a throttle body cleaner to remove any buildup.

Timely Replacements

Like any other component, the TPS has a lifespan. Replace it periodically to avoid unexpected breakdowns. It’s better to follow the manufacturer’s recommendations or consult with a specialist.

Conclusion

Having owned a 2000 Ford F250 7.3 for years, I’ve dealt with my fair share of TPS issues. With this comprehensive guide, I hope to empower you to identify and address these symptoms before they turn into major problems. Regular maintenance and timely diagnosis can go a long way in ensuring your truck’s longevity and performance.

For more detailed guides and troubleshooting tips, check out these resources:

Frequently Asked Questions

Q1: How often should I check the Throttle Position Sensor on my 2000 Ford F250?

A1: It’s advisable to inspect the TPS during regular maintenance intervals, roughly every 30,000 miles, or if you notice any symptoms mentioned in this guide.

Q2: Can I drive my truck with a faulty Throttle Position Sensor?

A2: While you can drive with a faulty TPS, it’s not recommended. It can lead to poor engine performance, increased fuel consumption, and unsafe driving conditions.

Q3: What are the costs associated with replacing a Throttle Position Sensor?

A3: The cost can vary but typically ranges between $100 to $200 for the sensor itself. If you opt for professional installation, labor costs can add an additional $50 to $100.

Q4: Can a bad TPS cause other engine issues?

A4: Yes, a malfunctioning TPS can cause a host of issues like erratic idling, stalling, and poor fuel economy, which can eventually lead to more serious engine problems if not addressed promptly.