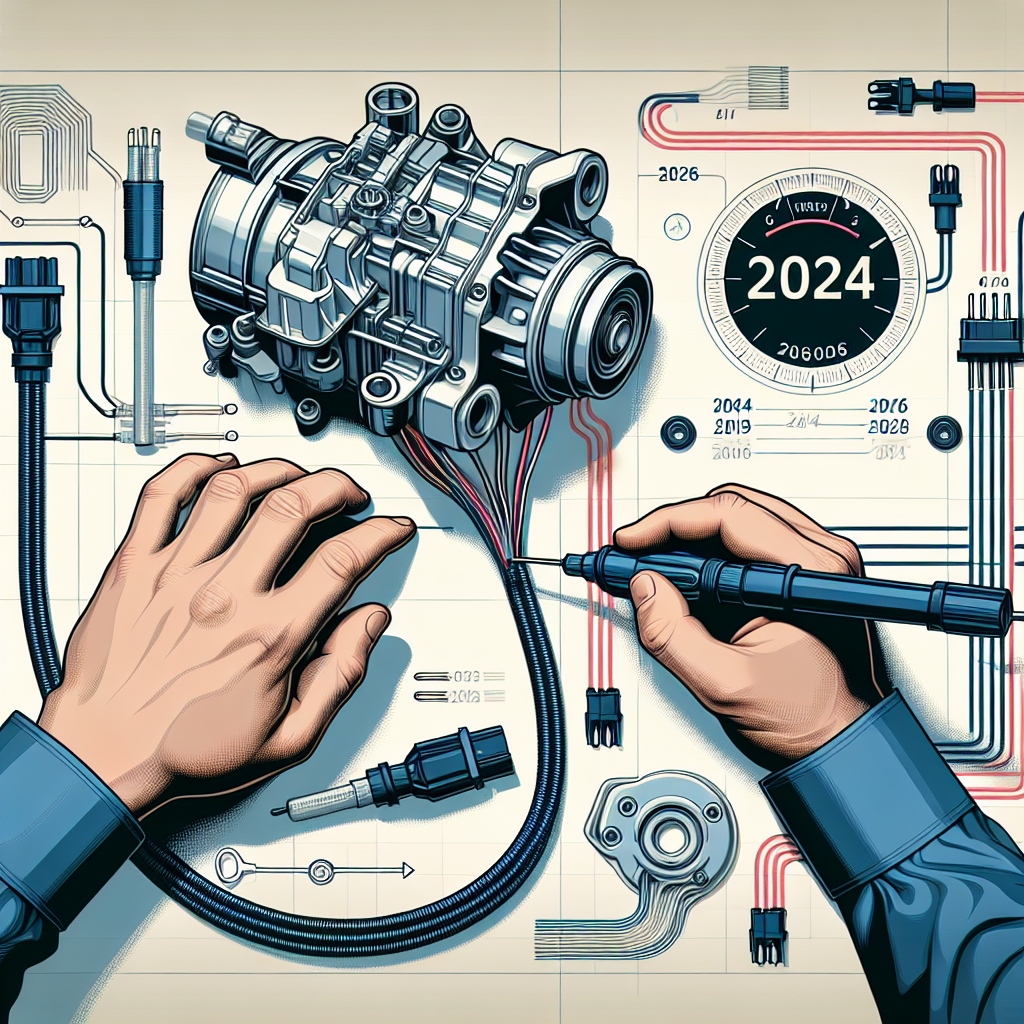

If you’ve been dabbling in car maintenance or upgrading your vehicle’s performance, you know the significance of getting your throttle position sensor (TPS) just right. The throttle position sensor is a vital component that reports the position of the throttle to an engine control unit (ECU), ensuring that your engine runs smoothly and efficiently. Wiring a 6-pin throttle position sensor might initially seem complex, but with this detailed guide, you will gain the confidence to tackle it head-on. Here is your ultimate guide to wiring a 6-pin throttle position sensor, based on first-hand experience.

Tools and Materials You’ll Need

Before diving into wiring your 6-pin throttle position sensor, gather all necessary tools and materials. Ensuring you have everything on hand will streamline the process and prevent interruptions.

Tools and Materials Checklist:

- Multimeter: To measure voltage and continuity

- Wire strippers: For cleanly cutting insulation off the wires

- Soldering iron and solder: For durable connections

- Heat shrink tubing: To insulate your connections

- Electrical tape: As an additional insulative measure

- Screwdrivers: Various sizes for removing and replacing components

- Service manual: Specific to your vehicle model for wiring diagrams

Understanding the Throttle Position Sensor

Basics of the Throttle Position Sensor

The throttle position sensor measures the angle of the throttle valve (butterfly valve). This information helps the ECU to determine the amount of fuel to inject, adjust ignition timing, and control other essential functions for optimal engine performance. Miswiring can lead to poor engine performance, increased fuel consumption, and even engine damage.

Types of Throttle Position Sensors

Throttle position sensors come in various configurations. The focus here is the 6-pin variant, which typically functions within more sophisticated, modern vehicles. Understanding the pin configuration and function is crucial before wiring.

Identify the Pins on the TPS

Typical Pin Configuration

Generally, a 6-pin throttle position sensor will include the following:

- Ground: This is the reference voltage for the sensor.

- Reference Voltage (usually 5V): Powers the sensor.

- Sensor Output: Sends signal to the ECU.

- Resistor Return: Completes the circuit for the potentiometer.

- Idle Switch: Indicates when the throttle is closed.

- Wide Open Throttle (WOT) Switch: Indicates when the throttle is fully open.

Using a Service Manual

A detailed service manual specific to your car model is invaluable. It provides vehicle-specific wiring diagrams that will help you identify each wire and its corresponding pin accurately.

Reading through detailed manuals, such as those provided by Haynes Manuals, can significantly aid in correctly identifying each pin and its function.

Wiring the Throttle Position Sensor

Step-by-Step Instructions

1. Preparation

Start by disconnecting the battery to avoid any electrical mishaps. Locate the throttle position sensor, usually attached to the throttle body of the engine.

Step-by-Step Wiring:

Remove the Old Sensor:

Unscrew and carefully detach the old sensor if you’re replacing it. Take note of how the old sensor was wired for reference.Connect Ground Wire:

Identify the ground wire on your 6-pin sensor. Use your multimeter to verify this pin by checking for continuity to the sensor body. Ensure a solid connection by soldering the wire and covering it with heat shrink tubing.Attach Reference Voltage Wire:

The 5V reference wire usually comes next. Verify its output with the multimeter. Solder the wire securely in place and use heat shrink tubing to insulate it.Connect Sensor Output Wire:

Next, connect the sensor output wire, which sends the throttle position data to your ECU. This connection must be strong and well-insulated to transmit accurate data.Wire Resistor Return:

Complete the circuit by connecting the resistor return wire. Miswiring this can lead to inaccurate readings.Attach Idle Switch Wire:

Connect the idle switch wire, which signals the ECU when the throttle is fully closed.- Connect Wide Open Throttle (WOT) Switch:

Finally, wire the WOT switch, which indicates when the throttle is fully open. This is crucial for performance tuning.

2. Testing and Verification

Once all connections are made, reconnect the battery and start the engine. Use the multimeter to verify that the sensor signals are within the expected ranges. This step ensures that the sensor communicates effectively with the ECU.

Delving Deeper: Troubleshooting Tips

Common Issues

Sensor Not Responding

If your throttle position sensor is not giving readings, check the ground and reference voltage first. Ensure there is no break in the wires and that all connections are secure.

Erratic Readings

Erratic sensor readings could be due to loose connections or electrical interference. Inspect all connections and ensure that the wires are not too close to high-voltage components.

Advanced Troubleshooting

If problems persist, use an OBD-II scanner to read any error codes from the ECU. This can offer targeted insight into what might be wrong.

Maintaining Your Throttle Position Sensor

Maintenance of the throttle position sensor can prolong its life and ensure optimum performance. Regularly check the wiring for wear and tear, and clean the sensor as per the manufacturer’s recommendations.

Frequently Asked Questions

1. What Happens if a Throttle Position Sensor is Miswired?

Miswiring can lead to inaccurate readings, poor engine performance, increased fuel consumption, and potential engine damage. Always refer to the vehicle-specific wiring diagram before proceeding.

2. Can I Use Any Multimeter for Testing the TPS?

Yes, any standard multimeter can be used. Ensure it can measure voltage and continuity as these are critical for testing the sensor.

3. How Often Should I Check My TPS Wiring?

Inspecting your TPS wiring every 6 months or during routine maintenance can help detect potential issues early on.

4. What Are Common Symptoms of a Faulty Throttle Position Sensor?

Common symptoms include erratic idling, poor acceleration, engine stalling, and increased fuel consumption. If these occur, check your TPS and its wiring.

For more detailed information on car maintenance, you might want to explore here and here. Similarly, visit this link for expert advice.