Complete Guide 2024: Understanding What a Crank Sensor Is and Its Function in Your Vehicle

Driving your car feels effortless, right? Well, that’s because modern vehicles are equipped with advanced technology that ensures everything runs smoothly. One of these crucial components is the crank sensor. This small device plays a big role in how your car operates. So let’s dive deep into this Complete Guide 2024: Understanding What a Crank Sensor Is and Its Function in Your Vehicle, and explore all facets of this essential part.

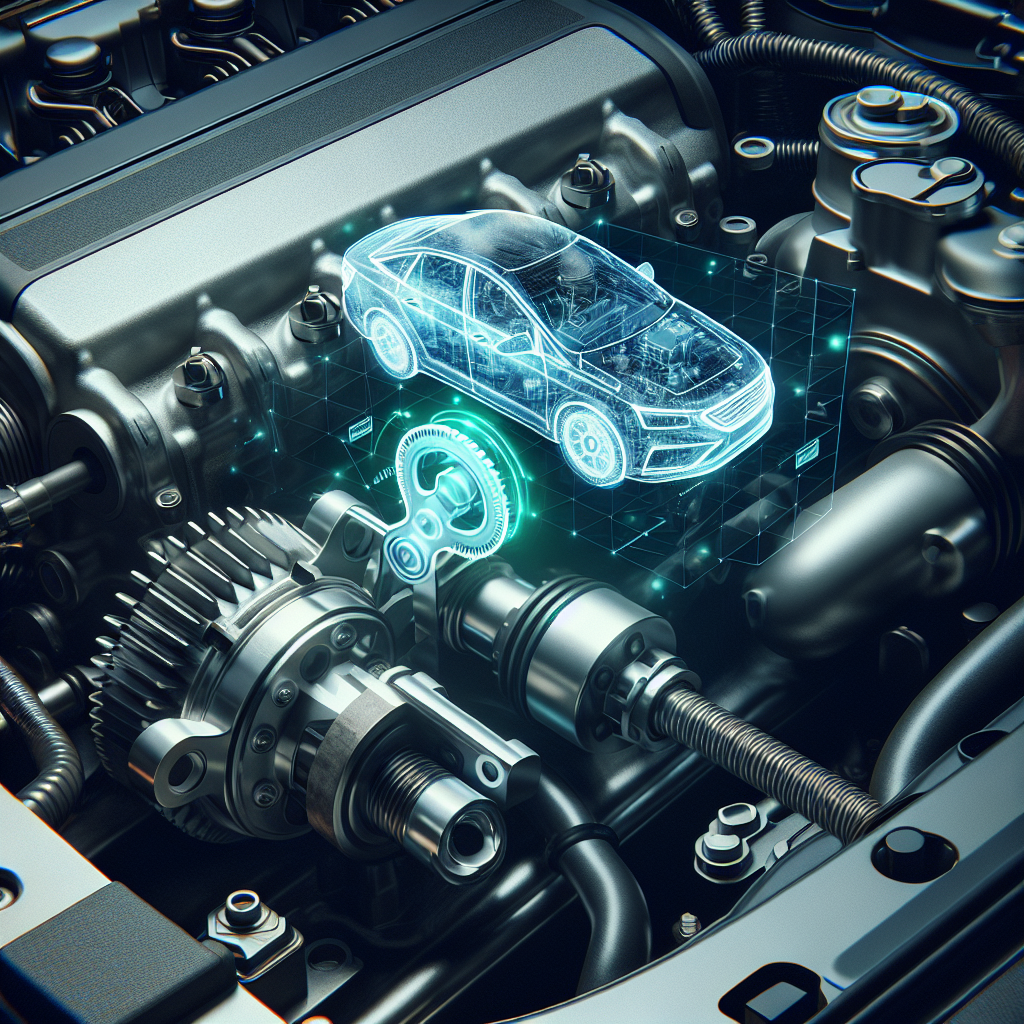

What is a Crank Sensor?

A crank sensor, also known as a crankshaft position sensor, is an electronic device in your car’s engine. Its primary role is to monitor the position and rotational speed of the crankshaft. This data is then transmitted to the engine control unit (ECU) to optimize the engine’s performance. Simply put, the crank sensor helps in the synchronization of the engine’s functions.

Why is the Crank Sensor Important?

Understanding the significance of the crank sensor can enhance your appreciation of your vehicle’s engineering. The crank sensor ensures that the engine’s systems are coordinated perfectly. Without it, your vehicle might suffer from inefficient fuel consumption, rough idling, and even complete engine failure. Knowing its importance can help you diagnose issues faster and maintain your car better.

How Does a Crank Sensor Work?

The Basic Principle

The crank sensor detects the crankshaft’s position using a magnetic field. When the crankshaft rotates, it disrupts this field, creating a voltage signal. This signal is then interpreted by the ECU to discern the position and speed of the crankshaft.

Key Components

- Magnet: Generates the magnetic field.

- Sensor: Detects disruptions in the magnetic field.

- Wiring: Transmits the signal to the ECU.

Understanding these components can help you identify where issues may crop up and how to address them.

Types of Crank Sensors

There are several types of crank sensors used in vehicles, and each has its own functionalities:

Hall Effect Sensor

Hall effect sensors use a Hall effect principle to measure magnetic fields. They are highly accurate and reliable, making them popular in modern vehicles.

Magnetic Inductive Sensor

Magnetic inductive sensors use inductive loops to generate a magnetic field. These are generally more durable and can function in harsher conditions.

Optical Sensor

Optical sensors use LED lights to detect crankshaft position. Though highly accurate, they are less common due to their sensitivity to dirt and debris.

Symptoms of a Faulty Crank Sensor

Recognizing the signs of a failing crank sensor can save you from costly repairs. Here are some symptoms to watch for:

Difficulty Starting

If your vehicle struggles to start, a faulty crank sensor could be the culprit. It fails to relay the necessary information to the ECU, causing ignition problems.

Engine Stalling

A crank sensor that intermittently fails can lead to engine stalling. It disrupts the timing of fuel injection and spark plug firing, causing the engine to shut off.

Rough Idling

If your car idles roughly, the crank sensor might not be providing accurate data. This imbalance can lead to inefficient fuel combustion.

How to Diagnose a Faulty Crank Sensor

Step 1: Visual Inspection

Before diving into more complex diagnostics, visually inspect the crank sensor for visible damage or loose connections.

Step 2: Use a Multimeter

A multimeter can measure the voltage output of the crank sensor. This can help you determine if it’s functioning within the specified range.

Step 3: Scan with an OBD-II Tool

Using an OBD-II scanner, you can check for error codes related to the crank sensor. This can provide a more detailed diagnosis.

Replacing a Crank Sensor

Replacing a crank sensor can be straightforward if you follow the correct steps:

Tools Needed

- Socket Wrench Set

- Screwdrivers

- New Crank Sensor

- OBD-II Scanner

Step-by-Step Process

- Disconnect the Battery: Ensure safety by disconnecting the car battery.

- Locate the Sensor: Refer to your vehicle’s manual to find the crank sensor.

- Remove the Old Sensor: Use your socket wrench set to unscrew and remove the old sensor.

- Install the New Sensor: Insert and screw in the new sensor, ensuring it’s secure.

- Reconnect the Battery: Reconnect the battery and start the car to check if the problem is resolved.

Preventative Maintenance Tips

Proper maintenance can prolong the life of your crank sensor. Here are some tips:

Regular Inspections

Frequently inspect your car’s engine bay for any signs of wear and tear. Early detection can save you from major issues.

Use Quality Parts

When replacing your crank sensor, always use high-quality parts. Using OEM parts ensures compatibility and longevity.

Keep It Clean

Ensure that your engine bay is free of dirt and debris. This can prevent damage to sensitive components like the crank sensor.

The Impact of Environmental Conditions

The performance of crank sensors can be affected by various environmental conditions. Understanding these can help you maintain your vehicle better.

Temperature

Extreme temperatures can affect sensor performance. Ensure your cooling system is in good condition to avoid overheating.

Moisture

Moisture can cause corrosion and disrupt electrical connections. Regularly check for leaks and keep your engine bay dry.

Debunking Common Myths

There are several misconceptions about crank sensors. Let’s tackle a few:

Myth 1: Crank Sensors Last Forever

No component is immune to wear and tear. Regular maintenance is key to prolonging its life.

Myth 2: All Crank Sensors Are the Same

Different vehicle makes and models have different requirements. Always refer to your vehicle’s manual when replacing parts.

Myth 3: A Faulty Crank Sensor Won’t Affect Fuel Efficiency

A crank sensor is integral to the engine’s timing and fuel injection. A malfunctioning sensor can lead to poor fuel efficiency.

Real-world Applications

Performance Vehicles

In high-performance cars, precise timing is crucial. High-quality crank sensors are essential for optimal performance.

Heavy-Duty Vehicles

Trucks and other heavy-duty vehicles often work in extreme conditions. Durable crank sensors ensure consistent performance in harsh environments.

Conclusion

Understanding what a crank sensor is and how it functions in your vehicle can vastly improve your car maintenance skills. By learning about its role, symptoms of failure, and how to diagnose and replace it, you can keep your vehicle running smoothly. Armed with this Complete Guide 2024, you’re well on your way to becoming more knowledgeable about your car’s inner workings.

Remember, the crank sensor, though small, is a crucial component. Its proper functioning is vital for the performance of your vehicle. So, keep an eye on it, perform regular maintenance, and you’ll avoid a host of problems.

Frequently Asked Questions (FAQs)

What is a crank sensor?

A crank sensor, or crankshaft position sensor, monitors the position and rotational speed of the crankshaft. This information is sent to the ECU to optimize engine performance.

How do I know if my crank sensor is faulty?

Symptoms include difficulty starting, engine stalling, and rough idling. Visual inspection, multimeter testing, and OBD-II scans can help diagnose the issue.

Can I drive with a faulty crank sensor?

Driving with a faulty crank sensor is risky. It can lead to poor fuel efficiency, engine stalling, and even complete engine failure.

How often should I replace my crank sensor?

There’s no specific time frame, but regular inspections can help you catch issues early. Replacing it as soon as you notice symptoms is advisable.

Further Reading

Remember, maintaining your crank sensor and understanding its functions can save you from inconvenient breakdowns and costly repairs. Your vehicle relies on many small but vital components working together, and the crank sensor is one such unsung hero. Through regular checkups and prompt replacements, you can ensure a smooth and safe driving experience.