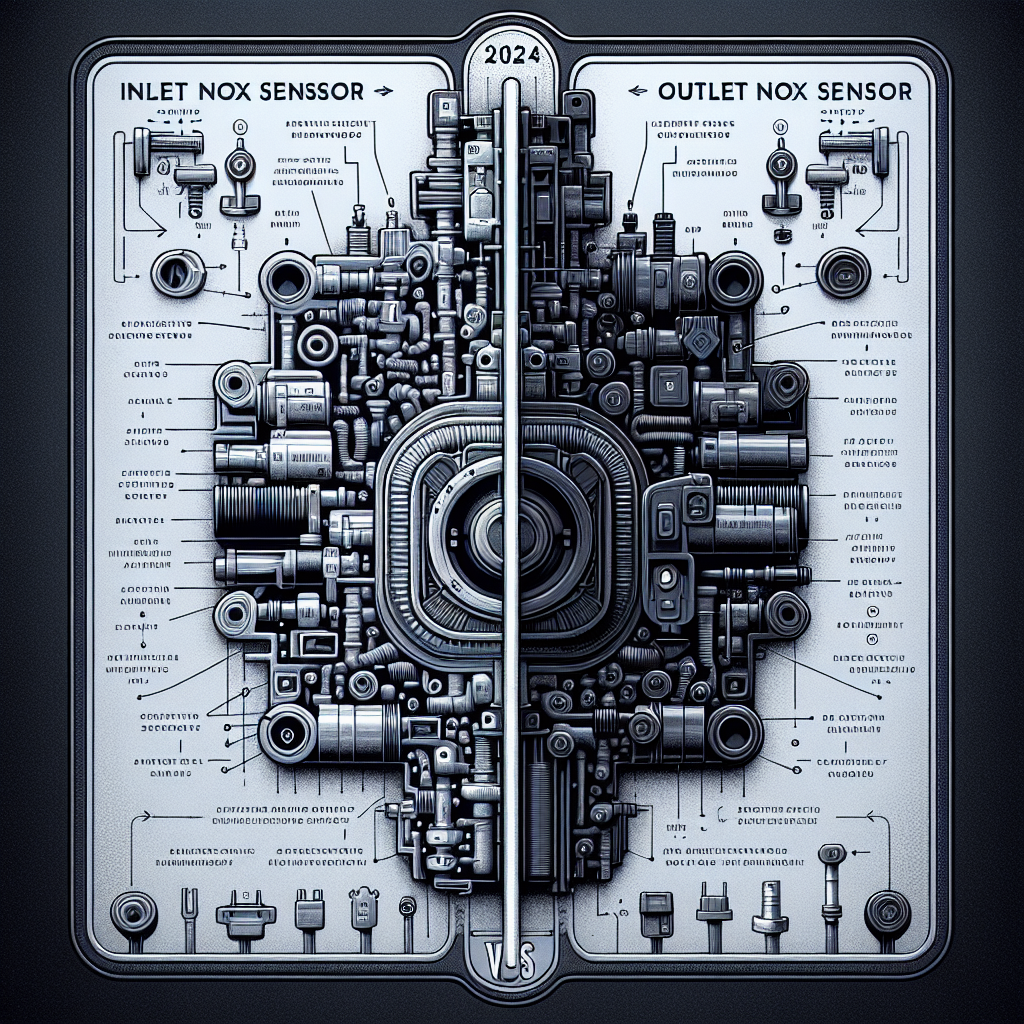

Inlet vs Outlet NOx Sensor: Key Differences Explained for 2024

As vehicle emissions standards become more stringent worldwide, technologies to monitor and reduce emissions have become integral parts of modern engines. Nitrogen Oxides (NOx) sensors are front and center in this effort, vital components instrumental in ensuring emissions stay within legal limits. In this detailed exploration, I will delve into the key distinctions between inlet and outlet NOx sensors, particularly in 2024 models, so you understand their functions, uses, and significance. I’ve worked extensively with these sensors in both industrial and vehicle settings, and this comprehensive guide draws upon that hands-on experience.

Understanding NOx Sensors: An Overview

Before diving into the differences between inlet and outlet NOx sensors, it’s crucial to understand what NOx sensors are and what they do. NOx sensors are devices that measure the concentration of nitrogen oxides in the exhaust gases that engines produce. These sensors are critical as NOx is a significant pollutant contributing to smog and acid rain.

What is an Inlet NOx Sensor?

The inlet NOx sensor is installed ahead of the Selective Catalytic Reduction (SCR) system, typically near the engine’s exhaust manifold. Its primary role is to measure the NOx emissions coming directly from the engine, before any exhaust after-treatment occurs.

Function and Importance of Inlet NOx Sensors

The inlet NOx sensor’s measurements are crucial for adjusting the engine’s combustion parameters. By monitoring the level of NOx produced during combustion, the engine control unit (ECU) can make real-time adjustments to fuel injection timings and exhaust gas recirculation rates. This calibration helps optimize combustion efficiency and reduces the formation of NOx.

Key Features:

- Placement: Before the SCR, close to the exhaust manifold.

- Function: Measures raw NOx emissions.

- Data Use: Helps in fine-tuning the combustion process.

What is an Outlet NOx Sensor?

In contrast, the outlet NOx sensor is positioned after the SCR system. Its main function is to monitor the amount of NOx remaining after the exhaust gases have passed through the SCR catalyst, where a urea-based solution (commonly AdBlue) is added to convert NOx into nitrogen and water.

Function and Importance of Outlet NOx Sensors

The critical role of the outlet NOx sensor is to ensure that the SCR system is effectively reducing NOx levels as expected. This involves providing feedback to the ECU, which may adjust urea injection rates to maintain optimal SCR performance.

Key Features:

- Placement: After the SCR system.

- Function: Measures NOx emissions post-treatment.

- Data Use: Verifies SCR efficiency and adapts urea dosing.

Key Differences Between Inlet and Outlet NOx Sensors

Here’s a table to succinctly summarize the key differences between inlet and outlet NOx sensors:

| Feature | Inlet NOx Sensor | Outlet NOx Sensor |

|---|---|---|

| Position | Before the SCR system | After the SCR system |

| Primary Function | Measure NOx levels pre-treatment | Measure NOx levels post-treatment |

| Role in System | Adjust engine combustion parameters | Verify and optimize SCR performance |

| Sensor Exposure | Exposed to high temperature and pressure | Exposed to treated exhaust, typically cooler |

| Data Utilization | Engine control & optimization | Emission compliance & SCR adjustment |

Application Insights: When and Where

The distinction between inlet and outlet NOx sensors becomes particularly crucial when considering their application in different types of vehicles and machinery. In high-performance engines, such as those found in trucks and heavy-duty vehicles, the efficiency of these sensors can significantly impact overall performance and compliance.

Advantages of Modern NOx Sensors in 2024

As we look into 2024, NOx sensors have advanced tremendously in their accuracy, durability, and responsiveness. Here are a few advancements:

- Improved Accuracy: Technological advancements have made current NOx sensors incredibly accurate. This precision allows for more refined control over combustion and exhaust treatment processes.

- Durability and Longevity: Modern NOx sensors are built to withstand extreme conditions, including high temperatures and pressures, ensuring consistent performance over time.

- Faster Response Times: Newer sensors feature faster response times, which means that adjustments to combustion and SCR systems can be made more promptly, improving overall efficiency.

Installation and Maintenance

Installation Guidelines

Installation of NOx sensors must follow specific guidelines to ensure they function correctly:

- Positioning: Ensure the sensors are installed at designated spots as improper positioning can lead to inaccurate readings and system inefficiency.

- Electrical Connections: Secure and protected electrical connections are crucial to avoid signal interference or data loss.

- Calibration: Post-installation calibration is critical to ensure accurate measurements.

Maintenance Tips

Maintaining NOx sensors involves several key practices:

- Regular Inspections: Regularly inspect for any physical damages or signs of corrosion.

- Cleaning: Sensors should be cleaned periodically to prevent soot or other deposits from affecting performance.

- Software Updates: Ensure that the ECU software is up-to-date to make the most of advanced sensor functionalities.

Technological Advancements in NOx Sensors for 2024

2024 has been a promising year for innovations in NOx sensor technology, focusing on efficiency and accuracy. Here are a few significant advancements:

- Enhanced Sensitivity: New sensor designs can detect even the slightest variations in NOx concentrations, which enables better monitoring and control.

- Miniaturization: The size of NOx sensors has significantly reduced, making them easier to install in various engine configurations.

- Wireless Connectivity: Some modern sensors now feature wireless capabilities, which simplify data transmission and reduce the need for extensive wiring.

Industry Standards and Regulations

NOx sensor performance is critical for complying with stringent emissions regulations. Here’s a brief overview of significant standards that influence the design and application of these sensors:

- Euro 6/VI: For both passenger cars and heavy-duty vehicles in Europe, NOx emissions must be significantly reduced.

- EPA Tier 4: In the United States, Tier 4 standards for off-road engines emphasize substantial NOx reduction.

- China VI: China’s rigorous VI standards also mandate significant reductions in NOx emissions from both on-road and off-road vehicles.

These regulations underscore the necessity of both inlet and outlet NOx sensors in ensuring emissions compliance.

Practical Insights: Real-World Applications

From my first-hand experience, implementing and maintaining NOx sensors reveals some practical insights:

- Fleet Management: In fleet management, regular monitoring of NOx sensor data can prevent costly repairs and downtime by identifying issues before they escalate.

- Performance Tuning: For performance enthusiasts, fine-tuning the engine based on NOx sensor data can lead to enhanced engine performance without compromising on emissions.

- Environmental Impact: Effective use of NOx sensor data contributes significantly towards reducing the ecological footprint of vehicles.

Comparative Performance

When comparing the performance of inlet and outlet NOx sensors, it becomes clear how they complement each other to ensure overall system efficiency:

- Data Synergy: The real-time data from inlet sensors helps in fine-tuning engine parameters, while outlet sensors ensure that after-treatment processes are effectively neutralizing NOx emissions.

- Reliability: Inlet sensors face harsher conditions and hence are built to withstand higher temperatures and pressures, whereas outlet sensors focus on post-treatment verification, requiring different durability characteristics.

Emerging Trends and Future Directions

Looking ahead, several emerging trends are expected to shape the future of NOx sensor technology:

- Integration with IoT: Future NOx sensors will likely integrate more seamlessly with Internet of Things (IoT) devices, enabling more comprehensive data analysis and remote diagnostics.

- AI and Machine Learning: Utilizing artificial intelligence and machine learning to predict and preemptively adjust engine and after-treatment parameters based on sensor data.

- Enhanced Diagnostics: New sensors will feature advanced self-diagnostic capabilities, making it easier to detect and rectify issues proactively.

Choosing the Right NOx Sensor

When selecting NOx sensors for specific applications, it’s essential to consider:

- Application Type: Heavy-duty versus light-duty vehicles have different requirements.

- Sensor Specifications: Temperature, pressure ranges, and response times.

- Compliance Needs: Ensure the sensors meet industry-specific regulations and standards.

Conclusion

The differences between inlet and outlet NOx sensors are fundamental to understanding how modern emission control systems work. Inlet sensors are essential for measuring and optimizing raw emissions from the engine, while outlet sensors ensure that the SCR system effectively reduces NOx levels. As advances in technology make these sensors more precise, durable, and faster, they are pivotal in helping meet stringent emissions standards and enhancing vehicle performance.

For further reading, you may refer to:

- Automotive NOx Sensors Explained

- Emission Control Technologies and NOx Sensors

- Modern Advances in NOx Sensor Technology

Frequently Asked Questions

Q1: What is the primary function of an inlet NOx sensor?

A1: The primary function of an inlet NOx sensor is to measure the concentration of nitrogen oxides (NOx) in the exhaust gases before they enter the Selective Catalytic Reduction (SCR) system, helping to adjust engine combustion parameters.

Q2: Where is the outlet NOx sensor located?

A2: The outlet NOx sensor is located after the SCR system. It measures the levels of NOx in the exhaust gases after they have been treated to ensure the SCR system’s effectiveness.

Q3: How do NOx sensors help in reducing vehicle emissions?

A3: NOx sensors help reduce vehicle emissions by monitoring NOx levels and providing real-time data to the engine control unit (ECU). This allows for precise adjustments in the combustion process and SCR system, ensuring optimal performance and emissions reduction.

Q4: What advancements can we expect in NOx sensors in 2024?

A4: Advancements in NOx sensors for 2024 include improved accuracy, enhanced sensitivity, miniaturization, and wireless connectivity, all contributing to better performance, easier installation, and more efficient data transmission.